Each diesel generator has its unique operational features. For imported brands, we need to pay more attention and take precautions. On the one hand, the price is relatively high when purchasing the machine. On the other hand, the maintenance cost is also relatively high. Therefore, when using it in daily life, the following points should be noted to avoid major accidents.

(1) The machine is operated under load without warming up after a cold start

When a diesel engine starts cold, due to the high viscosity and poor fluidity of the engine oil, the oil pump supplies insufficient oil. The friction surfaces of the machine are poorly lubricated due to lack of oil, resulting in rapid wear and even faults such as cylinder pulling and bearing burning. Therefore, after the diesel engine is cooled and started, it should idle to warm up. Only when the oil temperature reaches above 40℃ should it be operated under load. When starting the machine, you should shift into a low gear and gradually drive in each gear for a certain distance until the oil temperature is normal and the fuel supply is sufficient. Only then can you switch to normal driving.

(2) The diesel engine operates when the engine oil is insufficient

At this point, insufficient oil supply may cause inadequate oil supply to the surfaces of each friction pair, leading to abnormal wear or burning. For this reason, before starting the machine and during the operation of the diesel engine, it is necessary to ensure that there is sufficient engine oil to prevent cylinder pulling and bearing burning faults caused by lack of oil.

(3) Emergency shutdown under load or immediate shutdown after sudden load removal

After a diesel engine is turned off, the water circulation in the cooling system stops, and the heat dissipation capacity drops sharply. The heated parts lose cooling, which can easily cause overheating of components such as the cylinder head, cylinder liner, and cylinder block, resulting in cracks, or cause the piston to expand excessively and get stuck in the cylinder liner. On the other hand, if a diesel engine is shut down without idling to cool down, the friction surfaces will contain insufficient oil. When the diesel engine is restarted, poor lubrication will accelerate wear. Therefore, before the diesel engine is turned off, the load should be removed and the speed should be gradually reduced and the engine should run idle for several minutes.

(4) After a cold start of the diesel engine, suddenly rev the accelerator

If the throttle is slammed hard, the diesel engine speed will increase sharply, causing some friction surfaces on the machine to wear out severely due to dry friction. In addition, when the accelerator is pressed hard, the forces acting on the piston, connecting rod and crankshaft change greatly, causing severe impacts and easily damaging the components.

(5) Operate when the cooling water volume is insufficient or the temperature of the cooling water or engine oil is too high

Insufficient cooling water in a diesel engine will reduce its cooling effect, causing the engine to overheat due to ineffective cooling. Excessively high temperatures of the cooling water and engine oil can also cause the diesel engine to overheat. At this time, the main components such as the cylinder head, cylinder liner, piston assembly and valves are subject to large thermal loads, and their mechanical properties such as strength and toughness drop sharply, increasing the deformation of parts, reducing the fit clearance between parts, accelerating the wear of components, and in severe cases, cracking and component jamming faults may occur. Excessively high temperatures of cooling water and engine oil will accelerate the aging, deterioration and burning of the oil, and the viscosity of the oil will decrease. The lubrication conditions of the cylinder liner, piston and main friction pairs will deteriorate, resulting in abnormal wear. Overheating of a diesel engine can also deteriorate the combustion process of the diesel engine, causing the fuel injector to malfunction, resulting in poor atomization and an increase in carbon deposits.

(6) Operating under conditions where the temperature of the cooling water and engine oil is too low

During the operation of a diesel engine, if the temperature of the cooling water is too low, the temperature of the cylinder wall will drop accordingly. The water vapor produced by combustion condenses into water droplets, which come into contact with the exhaust gas to form acidic substances that adhere to the cylinder wall, causing corrosion and wear. Practical experience has shown that when diesel engines are frequently used at cooling water temperatures ranging from 40℃ to 50℃, the wear of their parts is several times greater than when they operate at normal working temperatures (85℃ to 95℃). At this time, when the water temperature is too low, the temperature inside the cylinder is low, and the ignition lag period of the diesel engine is prolonged. Once ignited, the pressure rises rapidly, and the diesel engine fuel becomes rough, which is prone to cause mechanical damage to the components. The diesel engine has been running for a long time at a relatively low temperature of the cooling water. The gap between the piston and the cylinder liner is large, resulting in knocking and vibration, which causes cavitation in the cylinder liner. When the engine oil temperature is too low, the viscosity of the oil is high and its fluidity is poor. The oil quantity in the lubrication parts is insufficient, which makes the lubrication worse, increases the wear of the friction pairs, and shortens the service life of the diesel engine.

(7) Operating under conditions of excessively low oil pressure

If the oil pressure is too low, the lubrication system cannot perform normal oil circulation and pressure lubrication, and each lubrication point will not receive sufficient oil. Therefore, during the operation of the machine, it is necessary to pay attention to observing the condition of the oil pressure gauge or the oil pressure indicator light. If the oil pressure is found to be lower than the specified pressure, the machine should be stopped immediately. Only after the fault is eliminated can the vehicle be driven again.

(8) The machine is traveling at excessive speed or overloaded

If the machine operates at excessive speed or overload, the diesel engine will run under conditions of excessive load and high speed, which can easily lead to rough operation. The thermal and mechanical loads on the cylinder liner, piston, connecting rod, etc. will increase, and faults such as cylinder pulling and bearing burning are likely to occur. Frequent overloading operation causes prolonged rough combustion inside the cylinder, which can easily damage the cylinder gasket.

(9) Slam on the accelerator before turning off the engine

If a high-speed diesel engine suddenly stops running, its huge inertia will cause damage to the parts of the crank connecting rod mechanism and the valve train, shortening their service life. At the same time, slamming on the accelerator causes excessive fuel to enter the cylinder and not be completely burned in time, flowing down along the cylinder wall and diluting the lubricating oil. In addition, it will also cause a significant increase in carbon deposits on the pistons, valves and combustion chambers, leading to clogging of fuel injectors and piston jamming.

(10) Suddenly add cooling water when the diesel engine temperature is too high

If cooling water is suddenly added to a diesel engine when it is short of water and overheated, it will cause cracks in the cylinder head, cylinder liner, cylinder block and other parts due to the drastic changes in temperature. Therefore, when the diesel engine temperature is too high, the load should be removed first, the speed slightly increased, and the diesel engine turned off after the water temperature dropped. Then, loosen the water radiator cap to release the water vapor. When necessary, cooling water can be slowly injected into the water radiator.

(11) Long-term idling operation

When a diesel engine is idling, the lubricating oil pressure is low, and the cooling effect of oil injection at the top of the piston is poor, resulting in a sharp increase in wear and an increased risk of cylinder pulling. It can also cause poor atomization, incomplete combustion, severe carbon deposits, and sometimes even lead to valve and piston ring jamming and cylinder liner cavitation. For this reason, some diesel engine user manuals clearly stipulate that the idle running time of the diesel engine must not exceed 15 to 20 minutes.

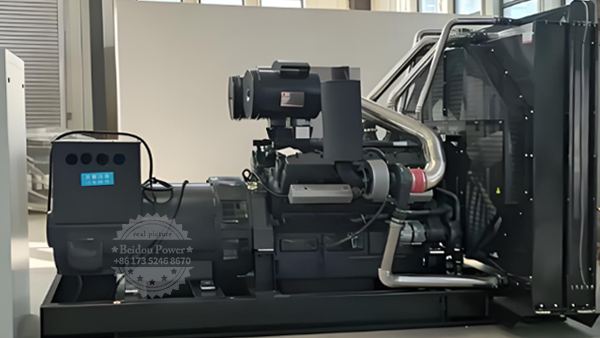

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Sep-29-2025