1. Check whether the surface of the unit is clean and tidy; Check if the anchor bolts, flywheel screws and other moving machine parts nuts are loose. If any problems are found, tighten them in time

Second, check whether the clearances of all parts are correct, especially carefully inspect whether the clearances of each intake and exhaust valve and the clearance of the pressure reducing mechanism meet the requirements.

Iii. Place each cylinder in the pressure-reducing position, rotate the crankshaft to listen for any abnormal sounds from the operation of each cylinder component, and check if the crankshaft rotates freely. At the same time, pump the oil into the friction surface. Then, close the pressure-reducing mechanism, shake the crankshaft, and check if the cylinders are leaking air. If it feels very difficult to shake the crankshaft, it indicates that the diesel generator set is compressing normally.

4. Check the condition of the fuel supply system. The steps are as follows:

Check whether the vent hole on the fuel tank cap is unobstructed. If there is any dirt in the hole, it should be cleaned thoroughly. Check whether the added diesel meets the required grade, whether the fuel quantity is sufficient, and turn on the fuel circuit switch. Open the decompression mechanism and rotate the crankshaft. Each cylinder should produce a clear sound of fuel injection, indicating good fuel injection. If you hear the fuel injection sound but no fuel comes in, there may be air in the fuel line. At this time, you can loosen the air release screws of the diesel filter and the fuel injection pump to remove the air in the fuel line. Check for any oil leakage at the oil pipe and joints. Deal with and solve any problems found in a timely manner.

V. Check the condition of the water cooling system. The steps are as follows

Check if the cooling water in the water tank is sufficient. If the water is insufficient, add clean soft water to top it up. Check if there is any leakage in the joint water pipes. If any problem is found, deal with and solve it in time. Check whether the impeller of the cooling water pump rotates flexibly and whether the tightness of the drive belt is appropriate. Check the tightness of the drive belt. Press it by hand in the middle of the rotating belt. It is appropriate for the drive belt to be pressed down by 10 to 15mm.

Six. Check the condition of the lubrication system. The steps are as follows:

Check whether there is any oil leakage at the oil pipe and pipe joints. Deal with and solve any problems found in time. Check the oil level in the oil pan. Pull out the dipstick beside the crankcase and observe whether the oil level meets the specified requirements. If not, add engine oil. For diesel engines, add No. 8 or No. 11 engine oil in winter and No. 14 engine oil in summer. During the inspection, if the oil level is found to be above the specified height, the reasons for the increase in engine oil should be carefully analyzed. Generally, there are three aspects of reasons.

A. When adding engine oil, too much was added.

B. Diesel leaks into the crankcase. Dilute the engine oil.

C. Cooling water leaks into the engine oil.

All oil holes that require manual oiling should be filled with engine oil and lubricated with grease using oil guns.

Vii. Check the starting system condition. The steps are as follows:

1. To start the diesel generator set, the steps are as follows

First, check whether the specific gravity of the electrolyte in the starting battery is within the range of 1.240 to 1.280. If the specific gravity is less than 1.180, it indicates that the battery power is insufficient.

B. Check whether the power supply wires are correct.

C. Check if there is any dirt or oxidation on the battery terminals and grind them clean.

D. Check whether the electrical contacts of the starting motor, electromagnetic control mechanism, etc. are in good condition.

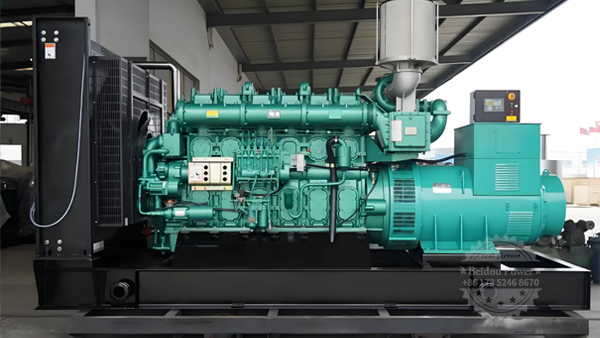

The installation and inspection steps for alternators are as follows:

When an alternator is coupled with a diesel generator, the parallelism and concentricity of the coupling should both be less than 0.05mm. In actual use, the requirements can be slightly lower, approximately within 0.1mm. Excessive backlash will affect the normal operation of the bearing and lead to damage. Good coupling should be fixed with locating pins. The coupling condition should be rechecked before installation.

2. When a generator with sliding bearings is coupled, the height of the generator center should be adjusted slightly lower than that of the diesel engine center. This way, the weight of the flywheel on the diesel engine will not be transferred to the generator bearing. Otherwise, the generator bearing will bear additional weight from the flywheel, which is not conducive to the formation of the oil film on the sliding bearing, leading to overheating and even burning out the bearing. No heavy objects should be placed on the couplings of this type of generator either.

When installing the generator, ensure that the cooling air inlet is unobstructed and avoid the hot air being discharged from entering the generator again. If there are louvers on the ventilation cover, the window should face down to meet the requirements of the protection level.

4. Special attention should be paid to the mechanical coupling of single-bearing generators to ensure that the air gap between the stator and rotor is uniform.

5. According to the schematic diagram or wiring diagram, select the appropriate power cable and connect it with copper joints. After the copper joint is securely fastened to the busbar and the busbar to the busbar, the local gap at the joint should not exceed 0.05mm, and the distance between the wires should not exceed 10mm. Additionally, necessary grounding wires should be installed.

6. The marks of U, V, W, and N on the terminal ends inside the generator outlet box do not indicate that the actual phase sequence depends on the rotation direction. The certificate of conformity is printed with UVW indicating the actual phase sequence when rotating clockwise, and VUW indicating the actual phase sequence when rotating counterclockwise.

7. If the neutral points of each generator in the power supply system are interconnected, or if the neutral points of the generators are connected to the neutral points of the transformers and their loads, a neutral line current of three times the frequency of the neutral line will be generated during the operation of the unit. Therefore, it is necessary to measure the neutral current of the generator under various load conditions that may occur during operation. To prevent the generator from overheating during operation, the line current must not exceed 50% of the generator’s rated current. If the power in the neutral line is too large, a neutral line reactor should be installed on the neutral line to limit it.

8. Adjustment of electrical parameters

The frequency of the unit is generally adjusted to 51.5HZ (for mechanical oil pumps), and for electronic speed-regulating units, it is generally adjusted to 50.0HZ. The unit voltage is 400V.

9. Gradually load

For the running-in of the entire machine, the first load of the unit should be gradually increased. The loading conditions are as follows: 25%, 50%, 75%, and 100%. Each stage should last no less than 30 minutes before reaching 75% load. Depending on the type of unit, it can be operated at 110% load for a short period to check the power performance of the unit.

10. Check the automatic protection function of the unit: such as low oil pressure, high water temperature, and overspeed. Adjust or simulate the above three abnormal states to test the protection and shutdown functions of the unit.

11. Check whether the unit has other functions.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jul-25-2025