Diesel engine noise is a complex sound source composed of multiple sound sources. According to the radiation mode of the noise, diesel engine noise can be divided into air dynamic noise and surface radiation noise. According to the mechanism of generation, diesel engine surface radiation noise can be further classified into combustion noise and mechanical noise. Among them, air dynamic noise is the main noise source.

(1) Air dynamic noise:

Air dynamic noise is generated due to the unstable process of gases, that is, by the disturbance of gases and the interaction between gases and objects. The air dynamic noise directly radiated into the atmosphere includes: intake noise, exhaust noise, and cooling fan noise.

1. Intake noise:

Intake noise is one of the main air dynamic noises of diesel engines. It is formed by the periodic opening and closing of intake valves, resulting in pressure fluctuations. When the intake valve opens, a pressure pulse is generated in the intake pipe, and as the piston continues to move, it is damped; when the intake valve closes, a pressure pulse with a certain duration is also generated. Thus, periodic intake noise is produced. The noise frequency components are mainly concentrated in the low-frequency range below 200 Hz. At the same time, when the airflow flows at high speed through the intake valve passage, turbulent shedding occurs, leading to the generation of high-frequency noise. Since the cross-section of the intake valve passage is constantly changing, the turbulent noise has a certain frequency range, mainly concentrated in the high-frequency range above 1000 Hz. When the natural frequency of the air column is consistent with the main frequency of the periodic intake noise, the resonance noise of the air column will also be more prominent in the intake noise.

For engines with turbocharging, since the rotational speed of the turbocharger is generally higher, the intake noise of turbocharged engines is significantly higher than that of non-turbocharged engines. The noise of the turbocharger is formed by the rotational noise generated by the periodic cutting of air by the blades and the turbulent noise formed by the high-speed airflow, and it is a continuous high-frequency noise, mainly distributed in the frequency range of 500 to 10,000 Hz. Currently, most of our company’s engines use turbocharging.

Intake noise is related to the intake method of the engine, the structure of the intake valve, the cylinder diameter, and the cam profile of the cylinder. For the same engine, the rated power is affected by the rotational speed, and when the rotational speed doubles, the intake noise increases by 10 to 15 dB(A).

2. Exhaust noise:

Exhaust noise is the main source of engine noise, and its noise is generally 10 to 15 dB(A) higher than the overall noise of the engine. Engine exhaust is high-temperature (800 to 1000°C) and high-pressure (3 to 4 atmospheres) gas. The exhaust process is generally divided into two stages: the free exhaust stage and the forced exhaust stage. The engine exhaust gas is ejected at high speed from the exhaust valve, enters the muffler along the exhaust manifold, and then is discharged into the atmosphere through the tail pipe. During this process, broadband exhaust noise is generated.

Exhaust noise contains complex noise components: exhaust noise with the exhaust frequency as the fundamental frequency, resonance noise of the air column in the pipe, airflow blowing noise at the exhaust manifold, exhaust injection and impact noise, Helmholtz resonance noise of the cylinder, Karman vortex noise, and turbulent noise inside the exhaust system.

The main factors affecting engine exhaust noise are: cylinder pressure, exhaust valve diameter, engine displacement, and the opening characteristics of the exhaust valve. For the same engine, engine speed and load are the main factors affecting its exhaust noise.

3. Cooling fan noise:

Fan noise consists of rotational noise and turbulent noise. Rotational noise is generated by the periodic cutting of air by the blades of the fan, resulting in pressure pulsations. The blade passing frequency is the fundamental frequency, accompanied by high-order harmonics. Turbulent noise is formed due to the turbulent separation of the surrounding air caused by the fan’s movement, which disturbs the air and leads to the process of gas compression and rarefaction. It is a broadband noise.

The noise of the cooling fan is affected by the rated speed. Doubling the speed can increase its sound level by 10 to 15 dB(A). At low speeds, the fan noise is much lower than that of the engine, while at high speeds, it often becomes the main noise source. Currently, the rotational speeds of the diesel engines used by our company are mostly 1,500 revolutions per minute, which belong to high-speed diesel engines.

(II) Surface radiation noise:

It is difficult to strictly distinguish between combustion noise and mechanical noise. Generally, the noise radiated outward from the cylinder through the cylinder head, piston-connecting rod-crankshaft-body is called combustion noise. The noise generated by the impact of the piston on the cylinder liner, the timing gears, the valve train, the fuel injection system, etc., and the mechanical impact vibrations between these moving parts is called mechanical noise. Generally, the combustion noise of direct injection diesel engines is higher than mechanical noise, while the mechanical noise of non-direct injection diesel engines is higher than combustion noise. However, at low speeds, the combustion noise is always higher than mechanical noise.

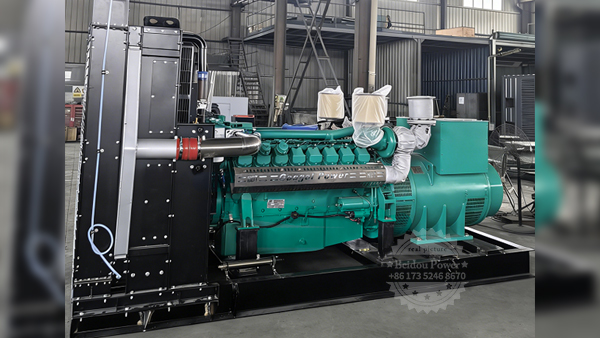

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Feb-04-2026