(1) There is no mechanical contact. The transmission force is generated in the air gap, and there is no other friction except for the guide rail.

(2) It features a simple structure, small size, and achieves linear drive with a small number of components, with only one moving part.

(3) The stroke is theoretically unrestricted, and its performance will not be affected by changes in the stroke.

(4) It can provide a very wide speed range, from a few micrometers per second to several meters per second, especially high speed is one of its prominent advantages: (5) The acceleration is very large, with a rated speed of up to 10g.

(6) The movement is smooth, which is because, apart from the linear guide rails or air bearing that serve as support, there are no other mechanical connection or conversion devices.

(7) High precision and repeatability are achieved as the intermediate links that affect accuracy are eliminated. The accuracy of the system depends on the position detection element, and with an appropriate feedback device, it can reach the sub-micron level.

(8) Simple maintenance: Due to the few components and no mechanical contact during movement, the wear of parts is greatly reduced. Only little or no maintenance is required, and the service life is longer.

Comparison Table of Transmission Performance between Linear Motors and “Rotary Motors, Ball Screws”

The disadvantages of linear motors are as follows: Firstly, the distortion of the magnetic field at the end of the linear motor affects the integrity of the traveling wave magnetic field, increasing the loss of the linear motor, reducing the thrust, and there is a significant thrust fluctuation. This is the unique “Edge Effect” of linear motors. The structural characteristics of linear motors determine that the end effect is inevitable. Secondly, the control of linear motors is difficult. During the operation of the motor, changes in load (such as workpiece weight, cutting force, etc.), system parameter perturbations, and various interferences (such as friction force, etc.), including end effects, all directly act on the motor without any buffering or weakening links. If the robustness of the control system is not strong, it will cause system instability and performance decline. Other disadvantages include difficult installation, the need for magnetic isolation, low efficiency and high cost.

In the manufacturing industry, the main type of motor that meets the feed system requirements of high-speed machining centers is the AC linear motor. Ac linear motors can be classified into two major categories: induction type and synchronous type. Although synchronous linear motors are more expensive, difficult to assemble and require shielded magnetic fields than induction linear motors, they are more efficient, have a simpler structure, do not require secondary cooling, are easier to control, and are more likely to achieve the required high performance. With the emergence and development of neodymium iron boron (NdFeB) permanent magnetic materials, permanent magnet synchronous linear motors will gradually become the mainstream. Therefore, the proportion of permanent magnet AC synchronous linear motors in high-speed machining centers will continue to increase.

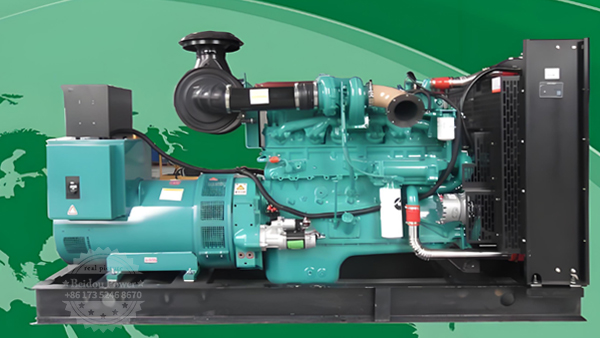

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-19-2025