Diesel generator is a generator driven by an internal combustion engine. It starts quickly and is easy to operate. However, the cost of generating electricity by an internal combustion engine is relatively high, so diesel generator sets are mainly used as emergency backup power sources, or in mobile power stations and in areas where large power grids have not yet reached. The rotational speed of diesel generators is usually below 1000 revolutions per minute, and the capacity ranges from several thousand watts to several thousand kilowatts. The majority of units with a capacity of 200 kilowatts or less are used. The manufacturing process of diesel generators is relatively simple. The torque output on the diesel engine shaft is periodically pulsating, so the generator operates under intense vibration conditions. Therefore, the structural components of the diesel generator, especially the rotor shaft, must have sufficient strength and stiffness to prevent these components from breaking due to vibration. In addition, to prevent the uneven rotation angular velocity of the generator caused by torque pulsation, resulting in voltage fluctuations and flickering lights, the rotor of the diesel generator also requires a large rotational inertia, and the natural torsional vibration frequency of the shaft system should be more than 20% higher than the frequency of any alternating component of the torque pulsation of the diesel engine to avoid resonance and prevent shaft breakage.

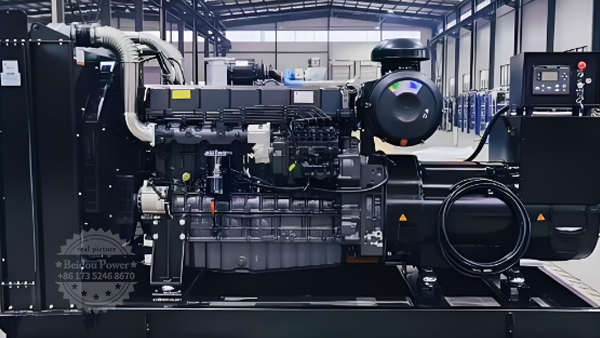

The diesel generator set mainly consists of a diesel engine, a generator, and a control system. There are two connection methods for the diesel engine and the generator: one is a flexible connection, that is, the two parts are connected together using a coupling; the other is a rigid connection, where the generator steel connection plate and the diesel engine flywheel disk are connected using high-strength bolts. Currently, the rigid connection is used more frequently. After the diesel engine and the generator are connected, they are installed on a common base frame, and then various sensors, such as water temperature sensors, are equipped. Through these sensors, the operating status of the diesel engine is displayed to the operator. With these sensors, a limit value can be set. When this limit value is reached or exceeded, the control system will give an early warning. If the operator does not take measures at this time, the control system will automatically shut down the unit. The diesel generator set takes this approach to protect itself. The sensors play the role of receiving and feedbacking various information. The actual display of these data and the execution of protection functions are carried out by the control system of the generator set itself.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jan-26-2026