When a generator is suspected to be faulty, a preliminary inspection can be conducted on the vehicle, and the generator can be disassembled for further testing without disassembling it. The tools used for detection can be multimeters (with voltage and resistance ranges), general DC voltmeters, DC ammeters and oscilloscopes, etc. It is also possible to make a small test lamp with a car bulb or a flashlight bulb, and the detection can be carried out by changing the working state of the car.

1. Vehicle inspection method: When it is suspected that the diesel generator set is not generating electricity, the generator can be inspected on the vehicle without disassembling it to roughly determine whether there is a fault.

1.1 Multimeter voltage range detection: Turn the multimeter knob to the 30V DC voltage range (or use an appropriate range of a regular DC voltmeter), connect the red probe to the generator’s “armature” terminal and the black probe to the casing. Let the engine run at a speed above medium. The standard voltage value for a 12V electrical system should be around 14V, and for a 24V electrical system, it should be around 28V. If the measured voltage is the battery voltage, it indicates that the generator is not generating electricity.

1.2 External ammeter detection: When there is no ammeter on the car dashboard, an external DC ammeter can be used for detection. First, remove the lead wire of the generator’s “armature” terminal. Then, connect the positive terminal of the DC ammeter with a range of about 20A to the generator’s “armature”, and connect the negative terminal wire to the aforementioned removed terminal. When the engine is running at a speed above medium (without using other electrical equipment), if the ammeter shows a 3A – 5A charging indication, it indicates that the generator is working properly; otherwise, the generator will not generate electricity.

1.3 Test lamp (car bulb) Method: When there is no multimeter or DC meter available, a car bulb can be used as a test lamp for detection. Weld wires of appropriate length to both ends of the bulb and attach alligator clips to both ends. Before the test, first remove the wires of the generator’s “armature” terminal. Then, clamp one end of the test light onto the generator’s “armature” terminal and ground the other end. When the engine is running at medium speed, if the test light is bright, it indicates that the generator is working properly; otherwise, the generator will not generate electricity.

1.4 Method of changing engine speed and observing headlight brightness: After starting the engine, turn on the headlights and gradually increase the engine speed from idle to medium speed. If the brightness of the headlights increases with the increase in speed, it indicates that the generator is working properly; otherwise, it is not generating electricity.

1.5. Remove the battery and ground it to check if the engine (gasoline engine) is working: This method can be used for detection when there is no microcomputer-controlled electronic device on the vehicle. Keep the engine at a medium speed or above, remove the grounding wire of the battery (usually disconnect the main control switch on the battery grounding wire). If the engine works normally, it indicates that the generator is generating electricity; otherwise, there is a fault with the generator.

2. Inspection and judgment without disassembly under the vehicle: After removing the motor from the vehicle, the following methods can be used for inspection to further determine the fault.

2.1. Judge with a small light bulb (flashlight bulb) : Connect the two ends of the flashlight bulb to wires to make a small test lamp, and connect it between the generator’s “armature” and the casing. Connect the positive and negative terminals of the battery (or a dry battery of the same voltage) to the two magnetic field terminals “F1″ and “F2″ of the generator respectively with wires (for an alternator with internal grounding, connect it to the “F” and “ground” terminals), and let the battery excite the generator. Quickly rotate the engine pulley by hand. A small test light indicates that the generator is working properly; otherwise, the generator will not generate electricity.

2.2 Multimeter Voltage range judgment: Let the battery excite the generator (the wiring method is the same as 2.1). Select the multimeter to the DC voltage range of 3-5V (or the appropriate range of a general DC voltmeter). Connect the black and red test leads to the “ground” and the generator’s “armature” terminals respectively. Rotate the belt pulley by hand. The pointer of the multimeter (or DC voltmeter) should swing; otherwise, the generator will not generate electricity.

2.3 Multimeter Resistance range detection and judgment: Use the R×1 resistance range of a multimeter to measure the resistance between each terminal (the resistance values of different models of generators vary. The table below shows the JF522A generator). Compare the values with the normal ones to determine whether the generator has a fault.

2.4 Oscilloscope method detection and judgment: Install the generator on the electrical test bench, connect the wires between the oscilloscope and the generator, control the generator at a medium speed, and the voltage waveforms corresponding to the normal operation of the generator and various faults are shown.

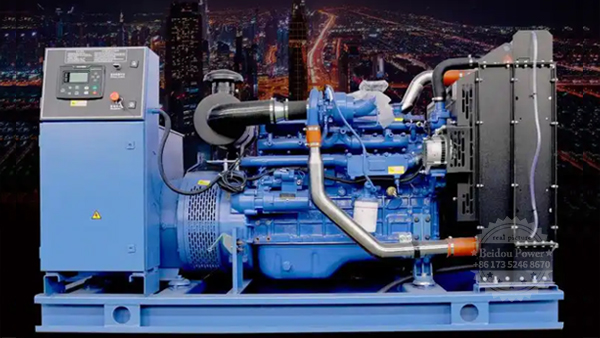

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jul-08-2025