Inspection and judgment of the technical condition of the plunger pair

(1) Observation method: Observe the marks on the severely worn parts. If there is a distinct feeling when scratching horizontally with a fingernail, a new part should be replaced.

(2) Empirical method: Clean the plunger pair thoroughly with diesel and fill the sleeve with diesel. Use your fingers to tightly block the oil inlet hole, oil return hole and center hole on the plunger sleeve. Then pull out the plunger to one-third of its length and release it. If it can immediately return to its original position, it indicates that it can continue to be used. Otherwise, new parts should be replaced.

(3) Pressure gauge inspection method: Connect a pressure gauge to the pump head, place the throttle at the rated oil supply position, open the pressure reduction and turn the engine to make the plunger pair pump oil at a speed of 30 times per minute. Then the pressure on the gauge must be greater than 19.6 kilopascals. Otherwise, new parts should be replaced.

2. Inspection and judgment of the technical condition of the oil outlet valve pair

(1) Observation method: Observe the sealing ring band. If it is concave and the width exceeds 0.5 millimeters, or if the pressure-reducing ring band shows obvious wear grooves and the original bright surface is no longer visible, a new part should be replaced.

(2) Oil pressure test method: Remove the high-pressure oil pipe of the cylinder under inspection, open the inspection window of the fuel injection pump, shake the plunger of this cylinder to the bottom dead center, use the hand oil pump to pump oil, first expel the air in the oil circuit, and then observe whether there is any leakage at the joint of the high-pressure oil pipe. If there is any leakage, a new part should be replaced (this method cannot inspect the pressure relief ring band).

(3) Pressure gauge inspection method: This inspection should be carried out simultaneously with the inspection of the plunger pressure. If the time required for the pointer of the pressure gauge to stabilize at 19.6 kilopascals and drop to 17.65 kilopascals after the oil supply is stopped is no less than 15 seconds, it indicates a good seal. Immediately cut off the oil supply after increasing the pressure to 24.52 kilopascals. Pay attention to the position of the pointer’s return swing. If it is between 0.98 and 6.87 kilopascals, it indicates that the decompression effect is normal. Only when the sealing is good can the exact value of the swing be seen.

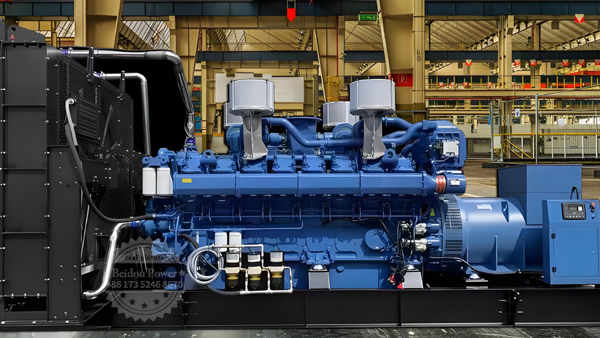

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: May-16-2025