(1). Aerodynamic Noise Control:

1. Intake Noise Control:

Most engines are equipped with air filters, which can significantly reduce intake noise and make it a secondary sound source. However, when other sound sources are further controlled, intake noise may become the main sound source. At this point, it is necessary to consider using a high-performance intake muffler. Usually, the intake muffler should be integrated with the air filter for an integrated design, which can not only meet the requirements of intake and filtration but also effectively control intake noise.

2. Exhaust Noise Control:

An effective method to control exhaust noise is to install an exhaust muffler. However, in practice, the noise reduction effect is often not very satisfactory. The main reasons are that the structure design of the muffler is not very reasonable and there are problems with the processing technology. The latter problem can be improved by enhancing the processing level; the former problem involves the design concept of the muffler. Usually, muffler design is mainly based on experience, and some design calculation programs are carried out under ideal assumptions. In these assumptions, the actual factor that affects the rated value is the existence of gas flow, and it is high-pressure, high-temperature, and high-speed pulsating gas flow. This state of gas flow will affect the sound field distribution, sound speed, and propagation laws inside the muffler, especially the gas flow velocity has a greater impact. The main reason for the influence of gas flow on the performance of the muffler is the high-speed pulsating gas flow from the engine exhaust that generates noise, and secondly, this gas flow will impact the pipes, shells, and acoustic elements of the muffler, thereby exciting vibration and radiating noise. When the structural parameters of the muffler are improperly selected or the structure is unreasonable, or there are problems with the processing technology, the muffler’s noise reduction performance will decline, and at the same time, excessive gas flow velocity will also increase the pressure loss of the muffler and cause a decline in noise reduction performance.

(2). Control of Engine Surface Radiated Noise:

The control of engine surface radiated noise (combustion noise and mechanical noise) is subject to various limitations in engine performance. From a technical perspective, it is very difficult and the noise reduction amount is limited. Practice shows that measures taken in the structure can reduce the engine’s surface radiated noise to a certain extent, thereby reducing the overall noise. The basic measure for control is to increase structural stiffness and damping, so that the response of the structural surface is reduced under the same excitation force. At the same time, reducing the surface area of radiated noise is also an effective measure for control.

(3). Practical Application of the Comprehensive Noise Control Concept:

For a 500 kW imported unit, the noise in the machine room can reach 105-108 dB(A). Without treatment, the noise outside the machine room is 70-80 dB(A) or higher, while the noise of a domestic unit with the same power parameter is even greater. Currently, when assessing whether environmental noise meets the standards, China adopts the “Urban Area Environmental Noise Standard” or the “Industrial Enterprise Boundary Noise Standard”. In these standards, there are different noise limits for different areas. Generally, in urban areas, it is Class I area, with a daytime limit of 55 dB(A) and a nighttime limit of 45 dB(A); in suburban areas, it is Class II area, with a daytime limit of 60 dB(A) and a nighttime limit of 50 dB(A). From the comparison data, it can be seen that the required noise reduction amplitude is very large, and the corresponding control technology is also very difficult.

For example, the oil generator room we previously treated had a fire prevention passage outside the intake, which could not be occupied. The intake muffler could only be installed inside the oil generator room, and the internal space design of the oil generator room was too small, resulting in the intake muffler being too close to the generator set, making it inconvenient for maintenance personnel to operate. To reduce the occurrence of the above problems and save investment in noise control treatment, by summarizing previous work experience, it is recommended that in the future, oil generator rooms be constructed with the following schemes: Try to reduce the number of doors and windows in the oil generator room to avoid the leakage of engine noise; Try to increase the distance between the air intake of the generator room and the generator foundation, extend the sound insulation distance, and build an intake small room; add an expansion chamber outside the exhaust outlet of the generator and try to extend the exhaust distance of the expansion chamber in the generator room.

If the above solutions can be adopted, the layout of the generator room will be more standardized and reasonable, the noise control in the later stage will be simpler, the construction mode will be standardized, and it will be easier to manage. With less investment, the environmental protection requirements can be met.

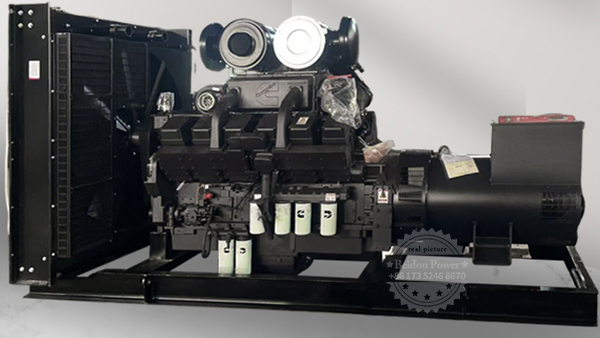

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Feb-06-2026