Gear damage during the operation of diesel engines is quite common. So, how can we quickly repair the normal operation of gears?

1. The reversing method causes unidirectional wear on the tooth surface of the gear. If the structure permits, the gear can be repositioned or flipped 180 degrees to use the unworn side. However, it is better to use them in pairs and flip them over, or replace the gears that work with them with new ones to ensure normal meshing of the gears.

Second, the gear ring insert method: The tower gear is made up of several gears together, and the degree of damage to each gear varies. For instance, if the teeth of individual gears are worn, the gear ring can be replaced for repair. First, anneal the gear to be repaired, turn off all the worn teeth, and then manufacture a gear ring and press it onto the part where the teeth have been turned off. To prevent the new gear ring from loosening, it can be fixed by spot welding along the circumference at the junction of the gear ring and the gear with electric welding, or by drilling holes and driving in stabilizing nails.

Iii. Gear embedding Method: For gears with low load and low speed, after individual teeth are knocked out, the gear embedding method can be used for local replacement. The repair agent planes out the root of the damaged gear teeth on a planer or a fitter makes a trapezoidal groove. Then, a new tooth blank of the same shape as the groove is pressed in with a certain tightness, welded firmly and processed into shape.

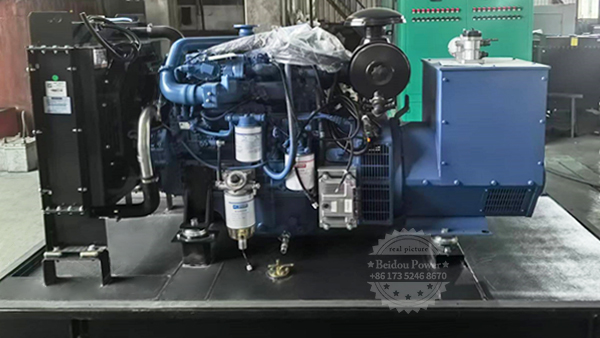

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Sep-15-2025