Working at low temperatures will aggravate the low-temperature corrosion of diesel engines and produce excessive low-temperature sludge. Working at high temperatures for a long time will accelerate the oxidation and deterioration of engine oil, intensify the gelling phenomenon in the high-temperature zone of piston rings, and generate excessive high-temperature deposits (paint films).

The purpose of maintaining a normal oil temperature during operation:

One reason is to prevent the temperature of the friction parts, especially the crankshaft bearings, from being too high, so as to avoid a decrease in the strength of the parts and an increase in wear.

Second, ensure that the oil pump has a large oil pumping capacity to guarantee reliable cooling and lubrication of the friction surfaces. The oil pumping volume of the oil pump is closely related to the temperature of the engine oil. If the temperature is too high or too low, the oil pumping volume will decrease. Only when the oil temperature is normal (about 85℃) will the oil pumping volume be rated. At this time, the viscosity of the engine oil is appropriate, which not only has good fluidity but also can reduce the backflow in the pump.

Thirdly, maintaining the normal temperature of the engine oil can reduce the oxidation rate of the oil at high temperatures, thereby extending the service life of the oil.

Methods for maintaining normal working temperature:

The temperature of the cooling water for diesel engines should be between 75 and 90 degrees Celsius, and must not exceed 95 degrees Celsius. The method to maintain the normal operating temperature of the diesel engine is that when the generator set starts, the insulation device in front of the radiator should be turned off, so that the heat absorbed by the diesel engine is greater than the heat dissipated, so that the diesel engine can heat up rapidly. During vehicle operation, if the diesel engine overheats, the insulation device should be turned on to ensure that the heat dissipation is greater than the heat absorption, so as to bring the cooling water temperature back to the normal range. If the diesel engine overheats but not seriously, the engine speed can be increased to make the heat dissipation greater than the heat absorption, thereby cooling down the diesel engine. You can also shift to a lower gear to reduce the load on the diesel engine and increase the engine speed to the operating speed at the same time, so that the water temperature can quickly return to the normal range.

It is particularly important to note that under no circumstances should the diesel engine be stopped for the purpose of “cooling down”. After the diesel engine is shut down, the cooling water no longer circulates, and the heat of the heated components cannot be carried away any longer. The temperature will continue to rise, causing local overheating and resulting in damage to some parts.

Use coolant with caution:

The manufacturer has strict requirements for the use of coolant in Cummins diesel generator sets, stipulating the use of long-lasting anti-freezing and anti-rust liquid. If water loss occurs due to long-term use or coolant leakage is caused by other reasons, distilled water or clean soft water (boiling water, rainwater, snow water) should be added. The soft water should be alkaline, with a pH value of 8.5 to 10.5. Untreated hard water such as river water, well water, spring water or tap water cannot be used as a substitute. Because under the effect of high temperature, minerals in these hard waters will precipitate from the water to form scale, which will clog the water jacket and radiator core, affect the cooling water circulation, reduce the cooling intensity and cause the diesel engine to overheat.

Coolant cannot be treated with “leak-proof” antifreeze. Although this type of leak-proof agent can automatically fill the gaps between the radiator and the circulating water channel within 2 to 3 minutes after being added to the radiator, it may clog the coolant filter.

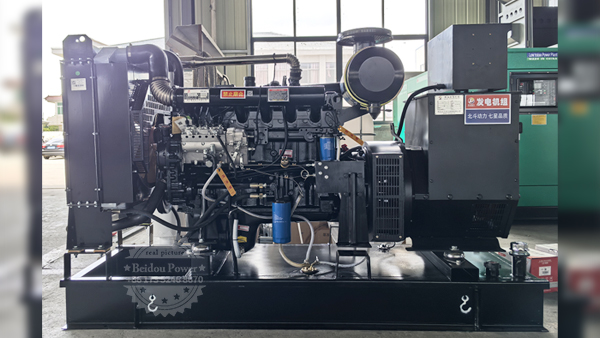

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Aug-08-2025