The fuel injection pump is an important component of the diesel engine’s fuel supply system. It is usually installed and used after adjusting the fuel supply on the test bench. Even so, abnormal situations such as insufficient power, black smoke from the exhaust, and unstable speed may still occur sometimes. This is mainly caused by the mismatch between the fuel supply volume adjusted by the fuel injection pump and the actual fuel volume entering the cylinder or the uneven fuel supply volume in each cylinder, which directly affects the power performance, economy and reliability of the diesel engine.

I. Reasons for Uneven fuel supply from the fuel injection pump

The difference between the debugging status and the usage conditions

The fuel injection pump is debugged at room temperature on the test bench, while it is used when the cylinder compression is completed, the cylinder temperature reaches 500 to 700℃, and the pressure is 3 to 5MPa. There is a significant difference between the two. When the locomotive is in operation, the temperature of both the fuel injection pump and the fuel injector reaches around 90℃, which can also cause the viscosity of diesel to decrease. As a result, the internal leakage of the plunger and needle valve pair increases, and the return oil volume is also more than during the debugging period. According to the measurement, the actual amount of oil injected into the cylinder by the fuel injection pump is only about 80% of the amount debugged on the test bench. Although the fuel injection pump debuggers will take this factor into account, it is impossible to accurately grasp it. In addition, due to the wear of the cylinder liner piston and the valve train or the different degrees of sealing, the temperature and pressure after compression in each cylinder will also vary. Even if the fuel injection pumps are debugged on the test bench, after installation and use, the fuel supply to each cylinder will still be uneven.

2. Uneven oil supply during debugging

When the fuel injection pump is being debugged on the test bench, it is required that the fuel supply unevenness of each cylinder at the rated speed should be less than 3%. During the actual commissioning process, due to the fact that the length, shape, and diameter of the fuel injectors and high-pressure oil pipes dedicated to the test bench cannot be exactly the same as those of the original machine, coupled with the differences in commissioning techniques, the unevenness of the actual fuel injected into the cylinder after the fuel injection pump is installed is often greater than 3%.

3. Uneven fuel supply caused by mechanical failure

After long-term use, if the coupling driven by the fuel injection pump of the locomotive becomes loose or has excessive clearance, the driving gears will wear out and the side clearance will increase, which will also affect the uniformity of fuel supply to each cylinder. In addition, leakage at high-pressure oil pipe joints due to frequent vibration or insufficient tightening, as well as excessive tightening force causing the metal at the joints to fall off and clog the oil pipes, can also lead to uneven oil supply to each cylinder.

Among the springs of the fuel injection pump and the governor, the plunger spring is the one that bears stronger force, undergoes greater deformation and operates at a higher frequency. So its breaking frequency is also relatively high. In mild cases, the fuel injection volume decreases, the fuel injection volume of each cylinder is uneven, the fuel injection interval time of each cylinder exceeds the tolerance, and the start time of fuel injection is delayed. In severe cases, fuel supply may be interrupted or even impossible.

Ii. Re-adjustment of the fuel injection pump after installation

The basis for readjusting the fuel injection pump

Based on the exhaust temperature, pressure or smoke color of each cylinder, judge its actual working condition and the combustion degree of the diesel engine, thereby determining whether the fuel supply to the cylinder is too much or too little, and whether the fuel supply time is too early or too late, and then make further adjustments. By appropriately adjusting the fuel supply volume and timing of each cylinder, the fuel injection pump can supply fuel to each cylinder of the diesel engine in accordance with the principle of on-demand distribution, thereby eliminating the actual differences among the cylinders.

2. Operation techniques for readjusting the fuel injection pump

After the fuel injection pump is installed, adjust the fuel supply time according to the specified standard and remove the exhaust manifold at the same time to observe the working conditions of each cylinder.

(2) Start the diesel engine and let it idle for 2 to 3 minutes. Touch the exhaust ports of each cylinder and the cylinder heads near the fuel injectors with your hand. If the temperature of a certain cylinder is too high, it can be initially determined that the fuel supply to that cylinder is excessive.

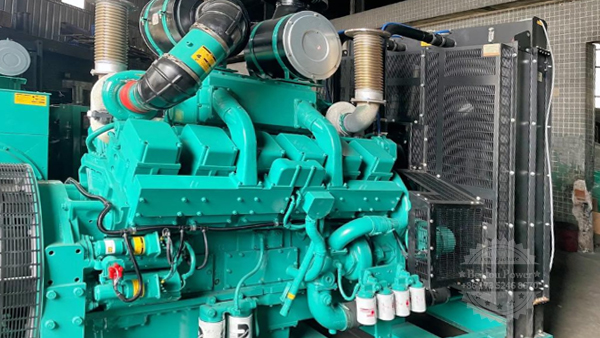

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jul-09-2025