The temperature of the generator’s sealing oil is high

The viscosity of sealing oil decreases as the oil temperature rises. Within the same flow area, to maintain a certain pressure of sealing oil, when the temperature of the sealing oil is high, a larger flow rate of sealing oil is required. The increase in the temperature of the sealing oil will lead to an increase in the gap of the sealing bearing, which also requires an increase in the flow rate of the sealing oil to maintain a certain pressure of the sealing oil. Generator manufacturers generally stipulate that the normal temperature of the sealing oil on the air and hydrogen sides of hydrogen-cooled generators should be between 27 and 50 degrees Celsius. For the 300MW steam turbine generator’s containerized sealed oil system, the outlet oil temperature of the cooler on the air and hydrogen sides of the sealed oil system is controlled by a drain regulating door and is generally maintained at around 42℃. The viscosity of the oil at 42℃ is lower than that at 27℃. To maintain a certain sealing oil pressure, a larger flow rate of sealing oil is required. Similarly, as the temperature of the sealing oil rises, the inner diameter of the sealing bearing will increase. To ensure that hydrogen inside the generator does not leak out, it is also necessary to increase the flow rate of the sealing oil to maintain a certain pressure. Therefore, if the temperature of the sealing oil is too high, it will lead to an increase in the flow rate of the sealing oil, which will also cause a decrease in the purity of hydrogen inside the generator or oil intake into the generator.

The oil flow from the sealing bush and the rotating shaft along the axial direction of the rotating shaft to the air side and the hydrogen side is called axial flow. When the pressure difference between the sealing oil on the air and hydrogen sides remains constant, the exchange volume of the sealing oil on the air and hydrogen sides is directly proportional to the gap of the sealing bush. For a 300MW steam turbine, the diameter gap of the sealing bearing is 0.15-28mm. When the gap of the sealing bearing increases from 0.15mm to 0.28mm during operation, the flow rate of the sealing oil will increase significantly. Due to the inevitable pressure difference between the sealing oil on the air and hydrogen sides, the increase in the flow rate of the sealing oil will lead to a multiple increase in the exchange volume of the sealing oil on both sides. The air, moisture and other substances carried in the air-side sealing oil enter the hydrogen-side sealing oil through exchange, and then enter the generator hydrogen through the contact between the hydrogen-side sealing oil and hydrogen, polluting the hydrogen and reducing its purity. An increase in the amount of sealing oil will cause the static pressure return oil pipeline to be blocked. When the oil level in the hydrogen side return oil chamber (defoaming box) of the generator rises above the low position of the journal, it will cause oil to enter the generator.

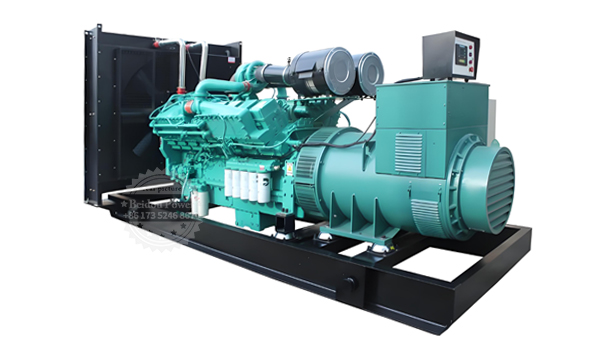

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jul-18-2025