When it comes to diesel generators, everyone should be quite familiar with them, but they may not be very proficient in or operate them correctly. So now let’s explore together the correct operation of generators and the consequences of improper use.

When a diesel generator starts cold, due to the high viscosity and poor fluidity of the engine oil, the oil supply from the oil pump is insufficient. The friction surfaces of the machine become poorly lubricated due to the lack of oil, resulting in rapid wear and even problems such as cylinder pulling and bearing burning. Therefore, after the diesel engine of a diesel generator is cooled and started, it should idle to warm up. Only when the oil temperature reaches above 40℃ should it be operated under load. When starting the machine, you should shift into a low gear and gradually drive in each gear for a certain distance until the oil temperature is normal and the fuel supply is sufficient. Only then can you switch to normal driving.

Sudden shutdown under load or immediate shutdown after sudden load removal – after the diesel generator is shut down, the water circulation in the cooling system stops, and the heat dissipation capacity drops sharply. The heated parts lose cooling, which can easily cause overheating of components such as the cylinder head, cylinder liner, and cylinder block, resulting in cracks, or cause the piston to contract excessively and get stuck in the cylinder liner. On the other hand, if a diesel engine is shut down without idling to cool down, the friction surfaces will lack oil. When the diesel engine is restarted, the wear will be accelerated due to poor lubrication. Therefore, before shutting down the diesel engine, the load should be removed and the speed should be gradually reduced and the engine should run idle for several minutes.

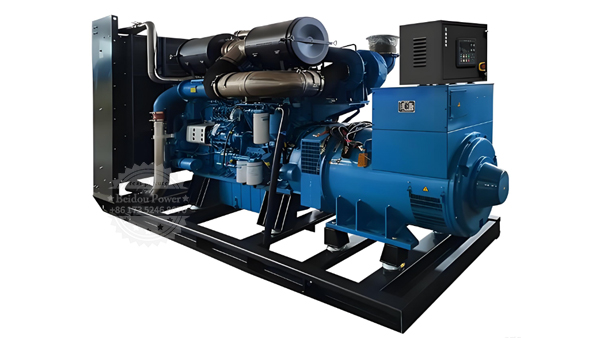

Beidou Power Generation Equipment Factory has been engaged in the research and development and production of diesel generator sets for many years. We have a thorough understanding of the various performance and operation requirements parameters of generator sets. We can provide you with generators of various brands and types, such as Volvo generators, Cummins generators, Weichai generators, Shangchai generators, Yuchai generators, silent generator sets, and noise-reducing generators.

Operating under conditions of insufficient cooling water or excessively high temperatures of cooling water and engine oil – a diesel generator lacking cooling water will reduce its cooling effect, causing the diesel engine to overheat due to ineffective cooling. Excessively high temperatures of the cooling water and engine oil can also cause the diesel engine to overheat. At this time, the main components such as the cylinder head, cylinder liner, piston assembly and valves are subject to large thermal loads. Their mechanical properties, such as strength and toughness, drop sharply, increasing the deformation of parts, reducing the fit clearance between parts, accelerating the wear of components, and in severe cases, cracks and component jamming problems may occur. Excessively high temperatures of the cooling water and engine oil in diesel generators will accelerate the aging, deterioration and burning of the engine oil. Moreover, the viscosity of the engine oil will decrease, and the smoothness conditions of the cylinder liner, piston and main friction pairs will deteriorate, leading to abnormal wear. Overheating of a diesel engine can also exacerbate the engine’s extinguishing process, causing the fuel injector to malfunction, resulting in poor atomization and increased carbon deposits.

When the generator set enters full-speed operation and the generator voltage and frequency are normal and stable, the operator can close the power generation air switch.

During the operation of the diesel generator set, the operator should also frequently observe and understand whether the unit is running normally, whether the instrument indication on the control panel is at the right position, whether there is a pre-alarm indication on the control panel, the fuel level in the fuel tank and other operating parameters, and record the operating parameters of the unit at regular intervals.

The emergency stop operation process of diesel generator sets

When an operator discovers that the unit has a serious fault or a power distribution fault, they can press the emergency stop button on the control panel to immediately shut down the unit. Under normal circumstances, it is not recommended that users shut down the unit at will by pressing the emergency stop button.

The normal shutdown operation process of diesel generator sets

Before the unit is shut down normally, the load should be separated first. Then, the unit should be run unloaded for a certain period of time to allow it to cool down fully before shutting down. For some units equipped with shutdown valves, the operation of stopping the unit by turning off the key switch on the control panel is ineffective. The correct shutdown operation must be carried out when the control panel is powered on and the shutdown button is pressed to stop the unit from running.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-10-2025