The development of linear motors abroad

Development history

The starting point of the development of linear motors is not much later than that of rotary motors. Shortly after the appearance of rotary motors in the world, the prototype of linear motors emerged. However, the development process of linear motors has been tortuous.

In 1845, the British Charles Wheastone invented the world’s first linear motor. However, this linear motor had very low efficiency due to the excessive air gap and failed to succeed. By the middle of the 20th century, the development of control, electronics, materials and other technologies provided theoretical and technical support for the development of linear motors, and linear motors began to enter a new stage of development. Professor E.R.Laithwaite from the UK was a pioneer in the development of modern linear motors. He emphasized the fundamental research of linear motors, and the research team led by him achieved many significant results. Another representative figure is Professor Kazuo Yamada from Japan, who has authored several books on linear motors. Since the 1970s, the application fields of linear motors have become more extensive, such as automatic plotters, liquid metal pumps (MHD), electromagnetic hammers, light industrial machinery, household appliances, air compressors and semiconductor manufacturing equipment, etc. After the 1990s, with the proposal of the concept of high-speed machining, linear motors began to appear as feed systems in machining centers. Due to the advantages and potential that direct drive feed systems have that traditional feed systems cannot match, they have once again received attention from various countries. According to relevant reports, the sales of USA’s linear motors and drive units were 45.53 million US dollars in 1997 and are expected to reach 107.72 million US dollars in 2002.

As an electromechanical system, the linear motor simplifies the mechanical structure and complicates the electrical control, which conforms to the development trend of modern electromechanical technology.

Anorad Corporation in the USA is a world-renowned manufacturer of linear motors. The company launched brushless DC linear motors in 1988 and obtained a patent in the USA. The company mainly produces permanent magnet synchronous linear motors, forming a series of products with different structures and powers, which are widely used in various fields.

The Indramat company in Germany produces both induction linear motors and permanent magnet linear motors, with over 50 models in total. Permanent magnet type features high efficiency (up to 1.72N/W) and high thrust density. It is reported that the speed of its product can reach 600m/min and the thrust can reach 22kN.

To reduce the price of linear motors, Trilogy Company has launched the Linear Coding Module (LEM). It uses the magnetic field of the motor to provide feedback on position, which is independent of the stroke. It can operate in harsh environments and provide commutation signals similar to those of full-travel sensors, with a resolution and repeatability accuracy of 5µm.

The products of other linear motor manufacturers each have their own characteristics. For details, please refer to “High-Frequency Response DC Linear Motor” by Liu Jinling et al. (published in “Micro and Special Motors”, Issue 4, 1993). The application of linear motors in the feed systems of high-speed machining centers and other large-stroke CNC machine tools in machine tools and machining centers is a relatively recent development. Machine tools equipped with linear motors must have advanced numerical control systems, high rigidity and natural frequencies, and the mass of moving parts should be as small as possible. Only in this way can the capabilities of linear motors be fully utilized. In addition, the design of the direct drive feed system in machine tools also needs to take into account cooling and heat dissipation issues. To prevent chips and various powders from being attracted by the open magnetic field of the linear motor, magnetic isolation and anti-magnetic measures must also be taken. In addition, linear motors are not self-locking like lead screws. If the motor is installed vertically, factors such as balance counterweight and braking also need to be taken into consideration.

The collaboration among Ford, Ingersoll and Anorad in the mid-1980s initially enabled the application of linear motors in machine tools. Ford Company hopes that its machine tools are both high-speed, high-precision and highly flexible. The result of the cooperation was that Ingersoll launched the “high-speed module” HVM800, with Anorad’s permanent magnet linear motors installed on all three axes, achieving excellent performance.

In 1993, the German Ex-Cell-O company showcased the world’s first high-speed machining center, the XHC240, which was driven by a linear motor on a worktable, at the European Machine Tool Exhibition in Hanover, Germany. It was equipped with an induction linear motor developed by the German Indramat company, with a maximum axis movement speed of 80m/min and an acceleration of up to 1g. Subsequently, many manufacturers successively launched machining centers equipped with linear motors. According to statistics, the sales volume of machine tools using linear motors was 300 units in 1997, and it is expected to increase to 3,000 units by 2005. In ten years, 20% of CNC machine tools will be equipped with linear motors.

In addition to cutting machine tools, other machine tools such as laser cutting, plasma cutting, and electrical discharge machining equipment have also begun to apply linear motors.

The research situation of domestic linear motors

Although there are many domestic institutions researching linear motors, there are mainly three universities that study linear motors as feed systems for machine tools or machining centers. Guangdong University of Technology has established the “Ultra-High-Speed Machining and Machine Tool Research Laboratory”, mainly researching and developing “ultra-high-speed electric spindles” and “high-speed feed units for linear motors”. They are researching linear induction motors and have developed the GD-3 high-speed numerical control feed unit for linear motors. The rated feed force is 2kN, the maximum feed speed is 100m/min, the positioning accuracy is 0.004mm, and the stroke is 800mm. Since the late 1990s, Shenyang University of Technology has been conducting research on permanent magnet linear synchronous motors and has manufactured a prototype with a thrust of 100N. Another key focus of their research is the control methods of electric motors and servo systems, and they have published many papers on this. The Institute of Manufacturing Engineering of the Department of Precision Instruments and Mechanical Engineering at Tsinghua University has successfully developed a high-frequency response DC linear motor with a stroke of up to 5mm, a cut-off frequency greater than 250Hz, and a thrust of several hundred Newtons. It is used to drive the transverse tool rest of a medium convex piston lathe and has achieved good application results in actual processing. The currently under research is a long-stroke permanent magnet linear servo unit. The rated thrust of the motor is 1500N, the maximum speed is 60m/min, the no-load rated acceleration is 1g, and the stroke is 600mm.

It should be noted that in China, the research on linear motors, especially linear servo motors in machine tool feed systems, is still in its infancy. There is a significant shortage of researchers and funds, and the progress is relatively slow. The gap with foreign countries is getting wider and wider. It is now extremely urgent to strengthen research. To break the technological monopoly of foreign countries, it is necessary to take the path of combining technological tracking with independent development, and strengthen the research on basic and key technologies.

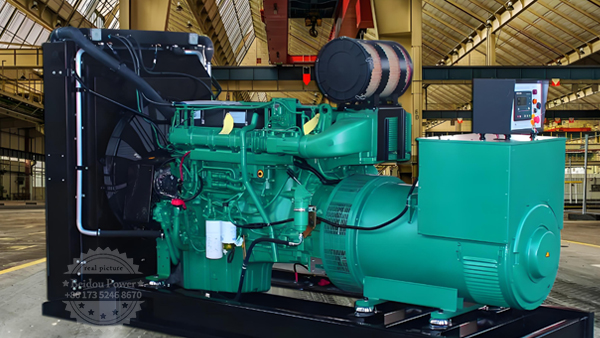

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-22-2025