Development trend

At present, the development of direct drive technology for linear motors shows the following trends:

Linear servo motors used in machine tool feed systems will be dominated by permanent magnet types.

Integrate the motor, encoder, guide rail, cable, etc., reduce the size of the motor, and facilitate installation and use

Modularize each functional component (guide rails, encoders, bearings, connectors, etc.)

Paying attention to the development of related technologies, such as position feedback components and control technology, is the foundation for improving the performance of linear motors.

Research direction

The research objective of linear motors is to enhance motor performance and meet application requirements. The main performance features of linear motors include speed, acceleration, thrust and its fluctuation, positioning accuracy, repeat positioning accuracy, mechanical characteristics (speed-thrust characteristics), transient performance (speed response), and thermal characteristics, etc.

As an electromechanical system, to enhance its performance, efforts can be made from both structural and control aspects.

Structural design

Linear motors consist of primary and secondary magnetic circuit structures as well as mechanical structures such as support, sensing and measurement, cooling, dust-proofing, and protection.

Magnetic circuit design

An important task of magnetic circuit design is to ensure that the thrust and thrust fluctuation of the motor meet the design requirements.

The calculation of the magnetic field distribution inside an electric motor is the basis of magnetic circuit design. Due to the particularity of its structure, linear motors have end effects, which cause distortion of the magnetic field. At the same time, soft magnetic materials such as silicon steel sheets are used to aggregate the magnetic circuit. The medium boundaries are tortuous and crisscrossing, the magnetic circuit is complex, and the nonlinearity is strong. If the traditional equivalent magnetic circuit method or graphical method is adopted for calculation, significant errors will occur, and it may even be impossible. Therefore, numerical solutions are currently widely adopted – mainly the finite element method (FEM) – to calculate the magnetic field distribution of linear motors, thereby further calculating thrust and its fluctuations, as well as vertical force and other performances. At present, there are already many excellent electromagnetic field FEM software available on the market for selection. Therefore, the key point in calculating the electromagnetic field of linear motors with FEM lies in establishing an accurate finite element model.

Reducing thrust fluctuations is a key and difficult point in magnetic circuit design. The causes of thrust fluctuations include: high-order harmonics in the primary current and back electromotive force, non-sinusoidal flux density waveforms in the air gap, cogging effect, end effect, etc. The thrust fluctuation can be reduced by optimizing the shape and arrangement of permanent magnets, lowering the magnetic flux density of permanent magnet excitation, adopting coreless and multi-pole structures in the primary stage, increasing the number of slots, and widening the air gap. However, some measures may cause the weakening of other performances. Therefore, when designing, the design requirements should be comprehensively considered to achieve the best effect.

Mechanical structure design involves many issues. Here, we only emphasize the research on the cooling system, as this issue is very easy to be overlooked. In fact, thermal characteristics are an important feature of linear motors. For the same model of motor, the peak thrust when cooled is twice that when not cooled. Therefore, the quality of the motor’s cooling system has a significant impact on the motor’s performance. Optimizing the design from the cooling system is a shortcut to improving the motor’s performance. The analysis of the thermal characteristics of electric motors generally also adopts the finite element method, and the cooling design is optimized based on the calculation results.

Research on control technology

Control technology is another key and difficult point in the design of linear motors.

When the linear servo system is in operation, it directly drives the load. Thus, changes in the load directly react on the motor. External disturbances, such as changes in the mass of the workpiece or tool, or cutting force, also act directly on the motor without attenuation. Changes in motor parameters also directly affect the normal operation of the motor. There is friction in the linear guide rail. Linear motors also have cogging effect and end effect. All these factors bring difficulties to the control of linear motors. In the control algorithm, these disturbances must be suppressed or compensated for; otherwise, it is easy to cause instability in the control system.

Overall, the design of the controller should meet the following requirements: high steady-state tracking accuracy, fast dynamic response, strong anti-interference ability, and good robustness. Different linear motors or different application scenarios have different requirements for control algorithms, so appropriate control methods should be adopted based on specific circumstances. At present, the control strategies adopted by linear servo motors mainly include traditional PID control and decoupling control, modern control methods such as nonlinear control, adaptive control, sliding mode variable structure control, H∞ control, intelligent control such as fuzzy control, and artificial intelligence (such as artificial neural network systems) control, etc.

It can be seen that the control algorithm of linear motors has a large amount of computation, and in the practical application of high-speed machining feed systems, it has strong real-time performance. Therefore, it puts forward very high requirements for the entire numerical control system. To meet this requirement, while optimizing the control algorithm, high-performance hardware should also be adopted. In the feed system of high-speed machining centers, all-digital drive technology is usually adopted, with PC as the basic platform and DSP for interpolation and servo control.

Although the control of linear motors is much more difficult than that of rotary motors, their electromagnetic characteristics and operating principles are basically similar, and the servo control technology of rotary motors has developed relatively maturely. Therefore, during the experimental research stage, in order to establish the experimental system as soon as possible to verify the feasibility of the design, we can also transform the servo controller of the rotary motor into a servo controller of the linear motor. This can reduce the cost and cycle of research and development and also has guiding significance for the development of dedicated servo controllers for linear motors.

Experimental research and theoretical research are the foundation of design, but to determine the performance of an electric motor, ultimately, it still depends on specific tests. The performance testing technology for rotary motors is already quite mature and standardized, but there is no unified method for the performance testing of linear motors yet. Therefore, researching efficient and precise performance test methods for linear motors is also a very important topic, which promotes theoretical research. The key points of the experimental research lie in the accurate measurement of various parameters such as speed, acceleration, static force, dynamic force, displacement, and temperature. If necessary, a dedicated test bench should also be designed. Based on the results of theoretical calculations, the design scheme is optimized. On this basis, a prototype is manufactured, and then the correctness of the design is verified through performance tests on the prototype. A high-performance linear motor often requires numerous repeated calculations and tests before it can be manufactured.

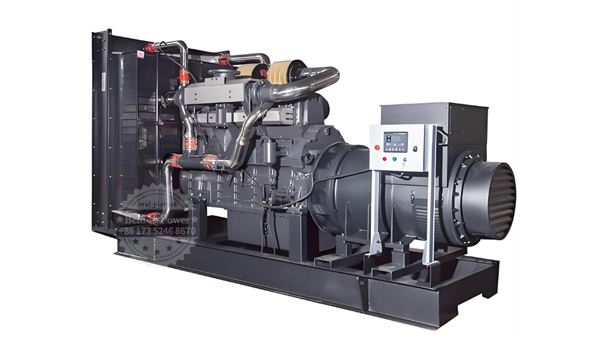

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-24-2025