The alternator utilizes the principle of electromagnetic induction to convert the mechanical energy driven by the engine to rotate the generator shaft into electrical energy for output.

According to Faraday’s law of electromagnetic induction, when the magnetic flux (the number of magnetic field lines) passing through the area enclosed by a closed loop changes (there is relative motion between the conductor and the magnetic field), an induced electromotive force will be generated in the loop. If the loop is a closed conductor loop, an induced current will be generated.

The alternator is designed and manufactured based on the above principle, but the magnetic field of the alternator is an electromagnetic field. When a current of a fixed direction is passed through two carbon brushes (for example, current flows into carbon brush A and out of carbon brush b), a magnetic field will be generated near the coil. The direction of the magnetic field is determined by the right-hand rule. To increase the strength of the magnetic field, a soft iron is inserted in the middle of the coil. When current is passed through it, a magnet is formed. The direction of the magnetic field lines around the magnet comes out from the N pole and returns to the magnet from the S pole to form a loop. A shaft is fixedly connected to the soft iron. When the engine drives this shaft to rotate, a rotating magnetic field is formed, causing relative motion between the wire and the magnetic field.

The characteristics of an alternator

Characteristics of AC generators (compared with DC generators) :

It features small volume, light weight and copper material saving.

2. Simple structure, reliable operation, convenient maintenance and long service life;

3. The engine has good low-speed charging performance (electromotive force is established through external excitation).

4. Advantages such as low radio interference;

5. The structure of the regulator used is simple (only a voltage regulator, which itself has the functions of current limiting and current cutting off).

Classification of alternators

(1) According to different overall structures

① Ordinary alternator

② Integral alternator

③ AC generator with pump

④ Brushless alternator

⑤ Permanent magnet alternator

(2) According to the different structures of rectifiers

① Six-tube generator

② Eight-tube generator

③ Nine-tube generator

④ Eleven tube generator

(3) According to the different grounding types of the magnetic field windings

① Built-in iron type

② External iron type

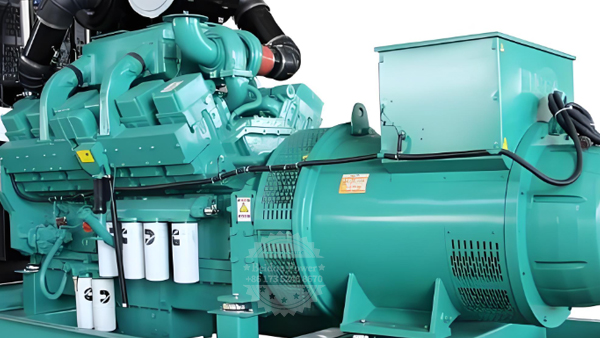

The structure of an alternator

1. Rotor: It is the magnetic field part of the generator (generating a rotating magnetic field), mainly composed of two claw poles, magnetic field windings, shafts and slip rings, etc.

Two claw poles are press-fitted onto the rotor shaft. The cavity of the claw poles is equipped with a magnetic yoke and wound with a magnetic field winding. The two leads of the magnetic field winding are respectively welded to two copper slip rings insulated from the shaft. Two brushes are in contact with the slip rings, introducing a DC power supply into the magnetic field winding. When excitation current is passed through the magnetic field winding, a magnetic field is generated. Among the magnetized claw poles, one is the N pole and the other is the S pole, thus forming 4 to 8 pairs of magnetic poles (the domestic JF series alternator has 6 pairs of magnetic poles).

The purpose of designing the rotor claw poles in a bird’s beak shape is to make the magnetic field present a sinusoidal distribution, so that the induced electromotive force generated by the armature winding has a better sinusoidal waveform.

2. Stator: It is the armature part of the generator (the stator is also known as the armature, generating three-phase alternating current), composed of the stator core and symmetrical three-phase armature windings, fixed between the two end covers. The stator core is composed of mutually insulated ring-shaped silicon steel sheets with grooves on the inner circle stacked together. The three-phase armature windings are mostly connected in star configuration, but there are also a few alternators that are connected in delta configuration.

3. End cover and cooling fan

The end covers are divided into the front end cover (drive end cover) and the rear end cover (rectifier end cover).

Its function is to install bearings and other components, support the rotor shaft, and seal the internal components.

It is made by die-casting aluminum alloy or sand mold casting. As aluminum alloy is a non-magnetic material, it can reduce magnetic leakage and has the advantages of being lightweight and having good heat dissipation performance.

The working characteristics of an alternator

The working characteristics of an alternator: It refers to the relationship between the DC voltage, current and rotational speed output by the generator after rectification, including output characteristics, no-load characteristics and external characteristics. Among them, the output characteristics are of great significance.

I. Output Characteristics

The output characteristics of an alternator, also known as load characteristics or output current characteristics. It refers to the relationship between the output current of a generator and its rotational speed when the output voltage of the generator is constant (14V for a 12V system and 28V for a 24V system), that is, the curve I=f(n) when the output voltage U is constant. The output characteristics of the alternator (which can be measured by experiments) are shown in the figure.

Ii. No-load Characteristics

The relationship between the terminal voltage of the generator and its rotational speed when the generator is no-load is called the no-load characteristic. That is, the functional relationship of U=f(n) when I=0.

Iii. External Characteristics

When the rotational speed is constant, the relationship between the terminal voltage of the generator and the output current is called the external characteristic, that is, the functional relationship of U=f(I) when n is a constant.

The output characteristic curve I = f(n) indicates that:

1. Rotational speed <” At n1, the generator terminal voltage is lower than the rated voltage and cannot supply power to the outside. When the rotational speed is n1, the voltage reaches the rated value. When the rotational speed is greater than n1, the generator supplies power externally at the rated voltage.

n1- no-load speed (when I=0 and U= rated voltage), the value of no-load speed n1 is the main basis for choosing the speed ratio of the generator to the engine. Generally, n1 should be equal to or slightly higher than the idle speed of the engine.

When the rotational speed is greater than n1, the output current of the generator increases as the rotational speed rises and increases as the rotational speed decreases. When the rotational speed is n2, the generator outputs the rated power (the product of the rated voltage and the rated current) or current.

n2- Full-load speed (or rated speed). Generally, the selected n2 should be lower than the engine’s maximum speed and equal to or slightly higher than the engine’s commonly used speed.

When the generator’s rotational speed reaches a certain value, the output current no longer increases with the rise in rotational speed or with the decrease in load resistance. That is, the generator has the self-protection ability to automatically limit the current. The current value at this time is called the rated output current or limiting current value of the generator (approximately 1.5 times the rated current).

No-load speed and full-load speed are the main performance indicators of alternators, both of which are stipulated in the product manual. As long as these two data are measured during use and compared with the specified values, it can be determined whether the performance of the generator is good.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-26-2025