I. Principles for Fault Diagnosis and Elimination of Diesel Generator Sets

1. To diagnose faults, an overall analysis should be conducted; to eliminate faults, a comprehensive approach is necessary

The various systems, components and parts of a diesel generator set are closely related. If one component, system or part malfunctions, it will inevitably affect other systems, components or parts. Therefore, a fault phenomenon cannot be viewed in isolation. It is necessary to analyze the cause of the fault as a whole and eliminate it in a timely manner.

When looking for faults in diesel generator sets, disassembly should be minimized as much as possible

When troubleshooting, one must not blindly disassemble the components of the diesel generator set. Before disassembling, it is necessary to first understand the structure, working principle, and faulty part of the diesel generator set. Only on the basis of scientific and careful analysis can disassembly be carried out.

3. When looking for faults, be meticulous and conduct a comprehensive inspection by combining observation, listening, touching and smelling

When troubleshooting, it is necessary to classify and search for the major systems of the diesel generator set

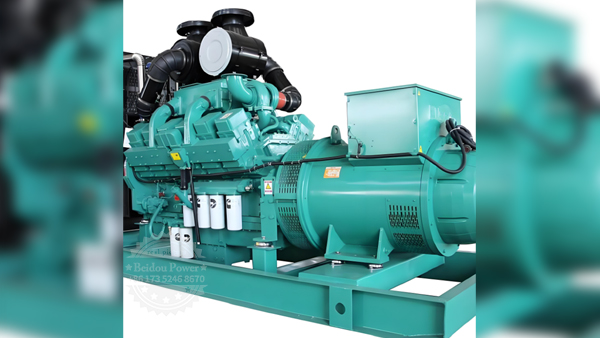

Diesel generator sets can be divided into two major parts: diesel engines and generators. Diesel engines have two major components and five systems. The two major components of a diesel engine are the stationary components and the relatively moving components. The five major systems of a diesel engine are:

(1) Fuel system: Its function is to ensure that fuel is injected into the combustion chamber at regular intervals, of the same quality and in the same quantity.

(2) Lubrication system: Its function is to ensure that there is a certain quality, quantity and pressure of lubricating oil on the friction surfaces of the moving parts of the diesel engine.

(3) Cooling system: Its function is to provide a certain quality and quantity of cooling water to cool the combustion chamber components and engine oil, enabling the combustion chamber parts to operate within the allowable temperature range.

(4) Valve train system: Its function is to open and close the intake and exhaust valves of each cylinder at regular intervals.

(5) Starting and charging system: Its function is to ensure reliable starting and charging lighting.

A generator is composed of a stator, a rotor, an automatic voltage regulating device and a power transmission control section, etc. The relationship between the stator and the rotor is that the generator rotor needs to be supplied with direct current to form fixed magnetic poles. When the rotor rotates, the stator cuts the magnetic field lines to generate alternating voltage. The function of the generator automatic voltage regulation device is: when the generator load increases (or decreases) or changes in nature, causing the generator terminal voltage to drop (or increase), it relatively increases (or decreases) the excitation current to keep the generator terminal voltage constant.

Any malfunction of the major systems of the diesel engine and the various components of the generator mentioned above will cause the diesel generator set to fail to operate normally.

Ii. Main Methods for Diagnosing Faults in Diesel Generator Sets

There are various methods for diagnosing faults in diesel generator sets. Currently, the most commonly used ones are the isolation method, the comparison method, the verification method, and the instrument and meter inspection method.

1. Partitioning method

The cut-off method involves stopping the operation of a single cylinder of the diesel engine or stopping the fuel injection of several or even all cylinders one by one, and observing the changes in the working state of the diesel engine before and after the fuel injection stops. This method is used to check the working conditions of each cylinder, especially to verify the effectiveness of the exhaust color of each cylinder.

2. Comparative method

The comparative method is widely used. After a diesel generator set malfunctions, if there is any doubt about a certain component or system, a high-quality component or a normal system can be replaced to observe whether the fault phenomenon has been eliminated. If the fault phenomenon disappears, it indicates that the fault occurred in this component or system.

3. Verification method

The verification method involves making tentative adjustments or disassemblies based on known causes of faults to check the correctness of past analyses and thereby identify the location of the fault.

4. Instrument and meter inspection method

The instrument and meter inspection method refers to the use of instruments or meters to test diesel generator sets, identify potential faults, and understand the performance and condition of the units.

In conclusion, for different fault phenomena, different methods for troubleshooting should be flexibly applied. One should start from the working principle and structure of the diesel generator set to find solutions to the problems.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Sep-10-2025