At present, in the fuel supply and chemical systems of some new brands of combine harvesters in the domestic market, mechanical fuel transfer pumps are still used to supply fuel to the low-pressure fuel lines. All the oil transfer pumps are equipped with manual oil pumping devices to meet the needs of manual oil pumping and air removal, etc.

So why does the manual oil pumping device often fail to pump oil? The main reason is that the elastic force of the return spring is greater than that of the diaphragm spring. When the top rod is pressed against the low point of the CAM, the diaphragm is in position. At this time, when the pressure rod is pulled, its eccentric finger cannot press the bottom edge of the square hole on the side of the pull rod assembly at all. Thus, the up and down movement process of the diaphragm, that is, the oil pumping process, cannot be completed.

Only when the push rod is within the range of the upper end of the CAM’s ascending stroke, that is, when the push rod is lifted upwards, the return spring is compressed, and the pull rod assembly is lifted by the diaphragm spring, will the eccentric finger of the push rod press down the pull rod assembly and the diaphragm through the square hole on the side of the pull rod assembly to complete the oil suction process when the push rod is rotated. Release the pressure rod, and the diaphragm spring can lift the diaphragm again to complete the process of pressurizing the fuel. Therefore, the key to pumping oil with a manual pump is to ensure that the hollow top rod is in the ascending stroke of the CAM. At high points, the stroke of manual oil pumping is rated, and the oil pumping effect is also good.

Pull the pressure rod by hand and confirm the feeling of your hand when you pull the pressure rod. If there is a strong sense of resistance when the pressure rod is pressed down, and there is a sudden increase in resistance during the 1/2 to 1/3 stroke after the pressure rod is pressed down, it indicates that the CAM position is appropriate. Just turn the pressure rod about 300 to 400 times to fill the filter. If there is no sense of resistance and there is no sudden increase in resistance during the last 1/2 to 2/3 stroke of the pressure rod, it indicates that the CAM position is not appropriate. You can turn the key switch to let the diesel engine idle for a moment and recheck the feel. Generally, idling four or five times is enough to make the CAM reach a better oil pumping position.

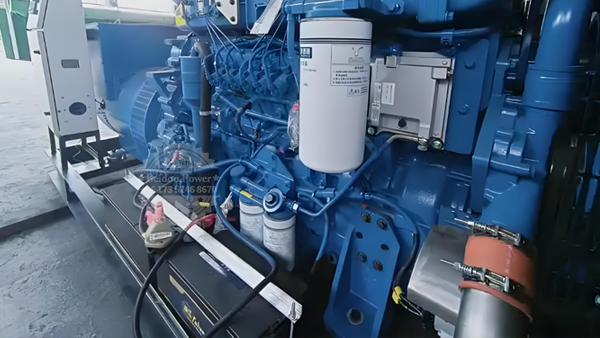

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jul-14-2025