In the design specification of power supply and distribution system of diesel generator set, emergency power supply should be added for important loads, which is the mandatory setting requirement of emergency power supply. In addition, considering economic, political and other factors, the standby power supply is set to prevent the loss of data caused by the normal power failure or the adverse impact of the political image. Based on the above situation, diesel generator set is used in many projects as emergency backup power. The following is a brief introduction to the design of diesel generators related content.

1. Advanced mechanical design

Using CAD computer aided design, CAE computer aided engineering, CAM diesel generator using computer aided manufacturing and other advanced means for mechanical design, and combined with advanced experimental means to design the colorful calibration scheme. Starting from the design details, the mechanical components of diesel generator set are constantly optimized to further improve the stability of diesel generator set.

2 Choice of diesel generator capacity

Generally in the scheme or preliminary design stage, we have no way to know the specific load situation, at this time, the capacity of the diesel generator set is 10 percent of the total capacity of the distribution transformer, in the specification and technical measures, 20 percent of the consideration. In the construction drawing design stage, when we determine the capacity of the required diesel generator set, we must first determine the load type of the diesel generator and the use of the diesel generator, that is, whether the diesel generator is used as a pure standby load, or the diesel generator is used as a normal load when the mains power is cut off. Standby load refers to the load of standby power set for the diesel generator project due to the requirements of fire protection and power supply guarantee. After weighing the advantages and disadvantages, the power supply load is determined to be a reasonable scheme, considering the reliability of power supply, economy and other factors. The capacity of the firewood generating unit can only be further determined after the power supply load of the project is determined.

3 Design power supply and distribution system of generator set

According to the number of diesel generator set, the nature of load, function and power supply requirements, there are many kinds of power supply system using diesel generator set as backup power supply. At present, the typical power supply systems commonly used in practical applications include: the generator set directly supplies power to the common load; Multiple generator sets in parallel supply power to common load; Single unit is used as standby power supply and municipal power supply for load power supply respectively; Multiple units and multiple transfer switches respectively supply power to the load; As the distribution system of medium and high voltage simple generator in common power supply; Medium and high voltage systems with multiple generators and municipal power supplies supplied by busbar or parallel load; A low-voltage generator uses a booster transformer to supply power to a low-voltage or medium-voltage distribution system. The power supply mode should be determined according to the power supply condition of the local network and the actual situation of load usage. The specific power supply mode should be determined based on the power supply and load usage of the local power grid. Among them, single unit as a backup power supply and municipal power supply respectively supply load, multiple units and multiple transfer switches are commonly used in many projects of low-voltage power supply and distribution system. When the capacity of the diesel generator set is large, generally not less than 8 kW, two diesel generator sets of the same capacity should be set. They can separately withstand part of the load or supply power to all the loads in parallel. At the same time, two diesel generators can also be set up for mutual backup. When one fails or requires regular maintenance, you can use the other as a backup power source and supply power to some load that requires priority or mandatory assurance. General diesel generator sets are not allowed to run side-by-side with the grid. The main consideration is that if the firewood generator unit fails, it may affect the market network and expand the fault impact surface. Therefore, firewood and mains are often used in interlocking to prevent the two from running side by side.

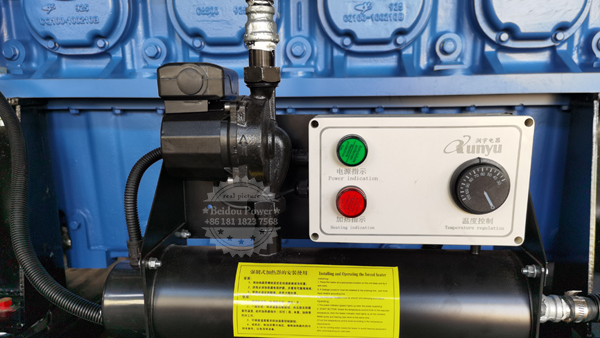

The starting mode and requirement of diesel generator set should also be determined according to the nature of load and power supply scheme. Unit control cabinet is generally provided by the manufacturer. Since the diesel generator set is usually started by power supply, municipal power supply required by the charger, battery and other startup equipment is required. The diesel generator room also needs to be configured with municipal power supply. When the diesel generator set is used as an emergency backup, when the normal power supply is the mains failure, the mains diesel generator conversion control system sends a signal to start the diesel generator set. When the mains is restored, the control system sends out a signal, the diesel generator is shut down, and the normal mains power supply is resumed. The core PLC control or integrated control unit is used in the conversion control system of the mains and firewood generating units, which generally requires overload and short circuit protection and other protection functions. When the capacity of the diesel generator set is insufficient, the secondary load can be unloaded. When the mains returns to normal, the unloaded load can be restored.

4. Site selection of diesel generator room

The diesel generator room is usually installed at the power load to avoid the increase of cable investment caused by too long lines and ensure the quality of power supply voltage. The selection of the location of the diesel generator room should also consider many factors during the operation of the diesel generator set. On the one hand, it is to ensure the operating environment of the unit itself, namely ventilation, exhaust and smoke exhaust. In this case, we will only consider burning diesel fuel, as most projects on the market today use diesel as fuel, and fuel supply and storage are also factors to consider in the room setup. During the operation of the diesel generator set, due to the diesel combustion will produce a lot of smoke, the diesel generator set itself produces gas and heat, which is not only unfavorable to the operation of the diesel generator set itself, but also causes environmental pollution to the activity site. Therefore, when selecting the location of the diesel engine room, exhaust smoke, gas, and heat away from the indoor and personnel entrances and exits to attract fresh air and create a good heat dissipation and ventilation environment. On the other hand, the diesel generator set will vibrate and produce noise during operation, which requires the site selection of the room to consider the impact of vibration and noise on the environment, and take reasonable measures to reduce vibration and noise when necessary. Considering the above factors, if the general conditions permit, the engine room can be located outdoors near the project, and away from the entrance and exit and crowded places. When conditions do not permit, many projects are also located in the underground level. Through the ventilation, exhaust, smoke exhaust, vibration and noise reduction measures, also run well, achieved good economic benefits.

5. Optimization design of diesel power generation base

The base of diesel generator set is the key component of diesel generator set, and its design level and machining accuracy directly affect the performance, vibration, noise, reliability and service life of the unit. The processing level of diesel generator base can only ensure the coaxiality of diesel engine and diesel generator. However, the influence of the deformation of the unit base on the coaxiality during the operation and hoisting of the unit needs to be checked from the point of view of the base design. On the premise of ensuring the material quality of the base of the unit, the checking calculation model of the base of the unit was established by combining the measurement experimental data, and the stress distribution of the key parts of the base of the unit under various states was analyzed by tampering with the limit count. Based on the finite element simulation, the structure of the base is optimized, and each improvement makes the base more solid and reliable. Another aspect of base optimization design is the design of unit vibration reduction system. The vibration reduction of the unit will affect the noise inside and outside the machine room: the vibration reduction performance of the unit is directly related to the dynamic load of the unit foundation and the vibration intensity of the unit components. The unit has excellent vibration reduction effect, which is conducive to noise reduction and prolong the service life of the unit.

Post time: Nov-30-2022