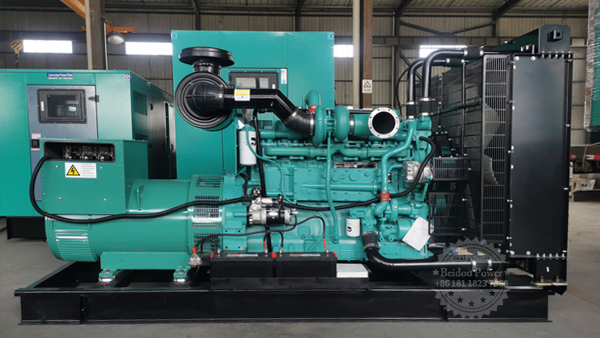

With the continuous development of microelectronics technology, automatic control technology and composite materials, diesel generators are developing in the direction of high motorization, miniaturization and intelligence. The continuous progress and update of related technologies have continuously improved the support capability and technical level of diesel generator sets, which will greatly promote the continuous improvement of comprehensive power supply support capabilities in various fields.

Chongqing Cummins diesel engines differ from spark-ignition engines in many ways. It has a high compression ratio, and only air, not the fuel mixture, enters the combustion chamber on the intake stroke. The Cummins fuel injector accepts low-pressure fuel from the fuel pump, and regularly and quantitatively sprays the fuel into each combustion chamber in a mist form for combustion.

Fuel ignition is caused by the heat of the compressed air in the combustion chamber. Knowing what is happening in the combustion chamber during each stroke of the piston’s four-stroke cycle makes it easier to understand the function of the various parts of the engine. The four strokes and sequence are: intake stroke, compression stroke, power stroke and exhaust stroke.

For a four-stroke to work properly, the actions of the valves and injectors must have a direct relationship with each of the four strokes of the piston. Intake valves, exhaust valves and injectors are driven by cams via cam follower arms or tappets, vertebral rods, rocker arms and valve crossheads. The camshaft is pushed by the crankshaft, so that the rotation of the crankshaft controls the action of the camshaft, which in turn controls the opening and closing sequence of the valves and the timing of fuel injection (fuel supply).

Intake stroke

At the end of the intake stroke, the intake valve closes and the piston begins to move upward into the compression stroke. At this point the exhaust valve remains closed. At the end of the compression stroke, the volume occupied by the air in the combustion chamber at the beginning of the compression stroke is compressed by the piston to a small volume (depending on the engine model, the compression volume is about 1/14~1/16 of the original volume). ). Therefore, the compression ratio is the ratio of the volume of air in the combustion chamber before and after compression.

Air is compressed into a small space, raising the temperature of the air high enough to cause the fuel to catch fire. At the end of the compression stroke, and at the beginning of the power stroke, a small amount of fuel is injected into the combustion chamber. Almost immediately after the fuel is injected into the combustion chamber, it is ignited by the hot compressed air in it.

Power Stroke

At the beginning of the power stroke, the burning and expanding gas pushes the piston down; the intake and exhaust valves are all closed. As more fuel is injected into the cylinders and burned, the gases are hotter and more expanded, pushing the pistons further down, which increases the driving force for the crankshaft to rotate.

Exhaust stroke

During the exhaust stroke, the intake valve closes, the exhaust valve opens, and the piston moves upward. The ascending piston forces the combusted exhaust gases in the combustion chamber to be expelled into the exhaust manifold through the open exhaust ports. The normal operation of the engine depends on two points. One is compression for ignition; the second is to inject the right amount of fuel into the cylinder at the right time.

Post time: Aug-05-2022